|  |  |

|

by John King - 2007

|

Text archive of On Plastic, written by John King. John King passed away in april 2009, but Nalu Music, his blog about ukuleles history, was still online. It has vanished from the web in August 2010, but can still be partly browsed on archive.org.

|

|

| |

A popular-priced, high quality professional instrument

he act of substituting experimental materials for traditional ones in the process of string instrument building is as old as the craft itself. The gradual discovery and implementation of new and better tonewoods, appropriate uses of slab and bias-cut lumber, improvements in design, and gains in the sciences of physics and acoustics have all contributed to the constantly evolving creative act of luthiery. Interestingly, the motives for change are as varied as the changes themselves: popularity, availability of raw materials, new musical styles, old musical styles, demands of recording and broadcasting—or performing plugged-in or unplugged—improved sound and playability, etc. However, the one factor overarching all these is economics and the mantra that has driven mass production is to make things cheaper, faster. he act of substituting experimental materials for traditional ones in the process of string instrument building is as old as the craft itself. The gradual discovery and implementation of new and better tonewoods, appropriate uses of slab and bias-cut lumber, improvements in design, and gains in the sciences of physics and acoustics have all contributed to the constantly evolving creative act of luthiery. Interestingly, the motives for change are as varied as the changes themselves: popularity, availability of raw materials, new musical styles, old musical styles, demands of recording and broadcasting—or performing plugged-in or unplugged—improved sound and playability, etc. However, the one factor overarching all these is economics and the mantra that has driven mass production is to make things cheaper, faster.

Not surprisingly, cheaper and faster are rarely, if ever, better or even the same as traditional methods and materials. A central theme in marketing mass produced instruments, stringed or otherwise, is the creation of a myth—great sound and playabilty at a fraction of the cost—at odds with the convential wisdom that you get what you pay for. In 1946, plastic harmonica developer Finn H. Magnus claimed his polystyrene reeds were “just as resilient as brass” and produced “mellower tones” although the performer had to “blow a little harder for his music.” Harmonica virtuoso Larry Adler disagreed. “As a musician I couldn’t possibly use it,” Adler declared. “It does not have the necessary range of color and musical expression. The manufacture of the harmonica must be as painstaking as making lenses.” But at a tenth the cost of a Hohner, with six shiny colors to choose from and “making a noise likely to soothe anybody who likes the harmonica—except Larry Adler and his peers…” Well, you get the picture. Magnus reduced the number of parts to five and the assembly to one operation for his plastic mouth organ, compared to no fewer than eighty parts and one-hundred fifty operations for a simple Hohner Marine Band harmonica. His ingenuity paid off; it made him a millionaire.

The development in the first half of the 20th century of synthetic materials—plastics—which could be milled, molded, or drawn into virtually any shape, or designed for nearly any use, had a profound effect on the manufacture of objects in general and musical instruments in particular. Introduced into peripheral items such as tuning peg buttons and bindings, materials like pyralin, Bakelite and nylon were quickly expanded into use as integral vibration-transmitting parts like reeds, strings, and nuts and saddles, replacing cane, gut, wood, bone and ivory. While much of the development of plastics occured in the 1930s—most significantly, polystyrene and nylon—widespread commercial exploitaton did not take take place until after the Second World War. The development in the first half of the 20th century of synthetic materials—plastics—which could be milled, molded, or drawn into virtually any shape, or designed for nearly any use, had a profound effect on the manufacture of objects in general and musical instruments in particular. Introduced into peripheral items such as tuning peg buttons and bindings, materials like pyralin, Bakelite and nylon were quickly expanded into use as integral vibration-transmitting parts like reeds, strings, and nuts and saddles, replacing cane, gut, wood, bone and ivory. While much of the development of plastics occured in the 1930s—most significantly, polystyrene and nylon—widespread commercial exploitaton did not take take place until after the Second World War.

In our own era change has been rapid and is nowhere more representative than in the ukulele family of instruments. Initially introduced into the Hawaiian Islands in the late 19th century, the forerunners to the ukulele (the machete and rajão) were constructed of woods native to the island of Madeira. Within twenty years of its importation the newly christened ukulele began to be made of Hawaiian hardwoods, most notably koa. Not only the backs and sides but the tops—traditionaly made of soft woods like spruce and pine—were made from the indigenous Hawaiian wood, a situation driven perhaps more by availabilty and cost rather than tonal considerations. The zenith of ukulele making in Hawaii was arguably reached by 1905, the year that Jose do Espirito Santo died. With the uke boom of the teens and twenties the mode of production moved from individuals hand-crafting instruments to factory operations both in Hawaii and on the mainland. As an enormously popular instrument, the uke was made incarnate in larger and larger forms from such seemingly disparate materials as wood, coconut shell, steel, tin, composition and plastic. With rare exception, the trend towards mass production lead to a cheapening of the instrument throughout the twentieth-century. In our own era change has been rapid and is nowhere more representative than in the ukulele family of instruments. Initially introduced into the Hawaiian Islands in the late 19th century, the forerunners to the ukulele (the machete and rajão) were constructed of woods native to the island of Madeira. Within twenty years of its importation the newly christened ukulele began to be made of Hawaiian hardwoods, most notably koa. Not only the backs and sides but the tops—traditionaly made of soft woods like spruce and pine—were made from the indigenous Hawaiian wood, a situation driven perhaps more by availabilty and cost rather than tonal considerations. The zenith of ukulele making in Hawaii was arguably reached by 1905, the year that Jose do Espirito Santo died. With the uke boom of the teens and twenties the mode of production moved from individuals hand-crafting instruments to factory operations both in Hawaii and on the mainland. As an enormously popular instrument, the uke was made incarnate in larger and larger forms from such seemingly disparate materials as wood, coconut shell, steel, tin, composition and plastic. With rare exception, the trend towards mass production lead to a cheapening of the instrument throughout the twentieth-century.

Consider the case of Harry E. Hall of Chicago, Illinois. When Hall filed a patent application in December 1925 for a mass-produced “sheet metal finger plate” for ukuleles, it was a milestone in the odyssey to low-cost and quick production. While Hall’s innovation eventually hit store shelves as a cheap brand called “Tru-Fret,” it had been his intention that the time and money saved by mass producing fingerboards would be lavished on better woods for the rest of the instrument: “Instruments of better tone quality than heretofore can be produced at a given price, not necessarily as a direct result of the tone qualities of the finger plate itself, as by reason of the great saving in price in the construction of the fingerboard, which makes it possible to put a better sound box in the instrument without increasing the total cost.” In practice the concept worked a little differently; inexpensive, mass produced fingerboards were attached to ukulele bodies made of inferior materials so as to further reduce costs and maximize profits. For instance, in the 1950s, ads for the Chicago manufacturer Harmony boasted that “Harmony creativeness and Harmony’s craftsmen teamed to produce this ingenious “Accurately Molded” polystyrene plastic fingerboard for moderately priced wood ukuleles. Offers fretting that is perfection itself. Mechanically exact - provides a freedom of technique hitherto unknown in low priced ukes.” Unfortunately the legacy left us by Harry E. Hall, at least with regard to ukulele construction, and notwithstanding his stated intentions, is this: vintage instruments constructed with molded, screw on fingerboards are the epitome of cheapness. Consider the case of Harry E. Hall of Chicago, Illinois. When Hall filed a patent application in December 1925 for a mass-produced “sheet metal finger plate” for ukuleles, it was a milestone in the odyssey to low-cost and quick production. While Hall’s innovation eventually hit store shelves as a cheap brand called “Tru-Fret,” it had been his intention that the time and money saved by mass producing fingerboards would be lavished on better woods for the rest of the instrument: “Instruments of better tone quality than heretofore can be produced at a given price, not necessarily as a direct result of the tone qualities of the finger plate itself, as by reason of the great saving in price in the construction of the fingerboard, which makes it possible to put a better sound box in the instrument without increasing the total cost.” In practice the concept worked a little differently; inexpensive, mass produced fingerboards were attached to ukulele bodies made of inferior materials so as to further reduce costs and maximize profits. For instance, in the 1950s, ads for the Chicago manufacturer Harmony boasted that “Harmony creativeness and Harmony’s craftsmen teamed to produce this ingenious “Accurately Molded” polystyrene plastic fingerboard for moderately priced wood ukuleles. Offers fretting that is perfection itself. Mechanically exact - provides a freedom of technique hitherto unknown in low priced ukes.” Unfortunately the legacy left us by Harry E. Hall, at least with regard to ukulele construction, and notwithstanding his stated intentions, is this: vintage instruments constructed with molded, screw on fingerboards are the epitome of cheapness.

Ukuleles Go Plastic

ut what about the all-plastic ukuleles first manufactured in the 1950s? There were many brands, and several patents, all for injection-molded polystyrene instruments of varying quality. The Strad of plastic ukes was Mario Maccaferri’s Islander, made by Maccaferri’s Mastro Plastics Corp. in the Cremona of the West: Bronx, New York. Highly collectible today, the original plastic Maccaferri ukuleles were made of Dow Styron polystyrene and had Du Pont nylon strings supplied by the National Musical String Co. of New Brunswick, New Jersey. In March, 1950, according to a report in Newsweek Maccaferri was turning out 2,500 ukuleles a day—almost one every thirty seconds—with a backlog of 100,000 orders on hand. Plans for the rest of 1950 included projected sales of half-a-million ukuleles. ut what about the all-plastic ukuleles first manufactured in the 1950s? There were many brands, and several patents, all for injection-molded polystyrene instruments of varying quality. The Strad of plastic ukes was Mario Maccaferri’s Islander, made by Maccaferri’s Mastro Plastics Corp. in the Cremona of the West: Bronx, New York. Highly collectible today, the original plastic Maccaferri ukuleles were made of Dow Styron polystyrene and had Du Pont nylon strings supplied by the National Musical String Co. of New Brunswick, New Jersey. In March, 1950, according to a report in Newsweek Maccaferri was turning out 2,500 ukuleles a day—almost one every thirty seconds—with a backlog of 100,000 orders on hand. Plans for the rest of 1950 included projected sales of half-a-million ukuleles.

That same month an article in the Wall Street Journal credited a TV personality—and plastic—with popularizing the ukulele anew:

Arthur Godfrey, Styron Spark Ukulele Comeback

The ukulele business is coming back with a loud twang, thanks to Arthur Godfrey and Dow Chemical’s plastic, Styron. The ukulele was popular shortly after World War I when Hawaiian music first came in. After that it pretty well passed out of the picture.

The boom got under way last Summer, when Mr. Godfrey appeared on television with a uke. Seeing it apparently started up public demand again. The difficulty was to get an instrument cheap enough for popular sale. Mario Maccaferri, head of Mastro Plastics, who got his start making plastic reeds for wind instruments, worked with Dow engineers to design the all-plastic uke. The ukes have nylon strings and can be played under water if any one wants to try it.

Maccaferri had originally planned to invest $10,000 and turn out a five-dollar toy, but reconsidered. “I know how to make the best,” he reasoned. “Why shouldn’t I use all my experience and make a real ukulele?” Why, indeed. When he finally had a product he was satisfied with, Maccaferri had gambled $75,000 on the success of the Islander but “had a much better instrument” than he expected. The major expense was for the four large molding presses that turned out the eight major parts of the ukulele: body, neck, and head (in one molded unit); the soundboard; the fingerboard, with molded-in frets; the bridge, the soundboard ring; the head cover; the inside sound bar; and the nut. Maccaferri’s five U.S. patents covered everything separately from the nut, soundboard, and bridge to the fingerboard and the method of making it. Compared to the simple patents of George Finder and David Rosenheim, Maccaferri’s ukulele patents look like rocket science, and in a way they really are blueprints for making space-age ukes. Maccaferri had originally planned to invest $10,000 and turn out a five-dollar toy, but reconsidered. “I know how to make the best,” he reasoned. “Why shouldn’t I use all my experience and make a real ukulele?” Why, indeed. When he finally had a product he was satisfied with, Maccaferri had gambled $75,000 on the success of the Islander but “had a much better instrument” than he expected. The major expense was for the four large molding presses that turned out the eight major parts of the ukulele: body, neck, and head (in one molded unit); the soundboard; the fingerboard, with molded-in frets; the bridge, the soundboard ring; the head cover; the inside sound bar; and the nut. Maccaferri’s five U.S. patents covered everything separately from the nut, soundboard, and bridge to the fingerboard and the method of making it. Compared to the simple patents of George Finder and David Rosenheim, Maccaferri’s ukulele patents look like rocket science, and in a way they really are blueprints for making space-age ukes.

According to one early report, the Islander came “in all colors, and one model is flourescent.” The official line was “simulated rosewood, with the head cover and soundboard in ivory.” Over the years, countless variants were made (if there is an official tally of the different colors I have not seen it). Like Magnus and his plastic harmonica before him, Maccaferri reduced the number of parts needed to assemble an ukulele from about twenty-one for a wooden instrument, to eight for the Islander—excluding the strings and tuning pegs. According to one early report, the Islander came “in all colors, and one model is flourescent.” The official line was “simulated rosewood, with the head cover and soundboard in ivory.” Over the years, countless variants were made (if there is an official tally of the different colors I have not seen it). Like Magnus and his plastic harmonica before him, Maccaferri reduced the number of parts needed to assemble an ukulele from about twenty-one for a wooden instrument, to eight for the Islander—excluding the strings and tuning pegs.

An article in Modern Plastics outlined the difficulties Maccaferri overcame with his design:

One of the largest problems encountered during the pre-production days of the Islander was the selection of a maerial formulation that would have all the properties and characteristics necessary for the particular application. Four months were spent on the choice of a material—one that would withstand the tension of the strings, one that would not distort or shrink during the life of the instrument, and one that would produce the correct pitch, resonance, and tonal quality. The final polystyrene formulation chosen combined the above requirements with resistance to the effects of dryness, moisture, heat, or cold.

Another production problem that had to be solved was the proper selection of an adhesive. The wrong adhesive would result in either shrinkage of the polystyrene or a marked deadening of sound in the completed instrument. According to the manufacturer, the selected adhesive further strengthens the polystyrene parts against the effects of dryness, moisture, heat, or cold.

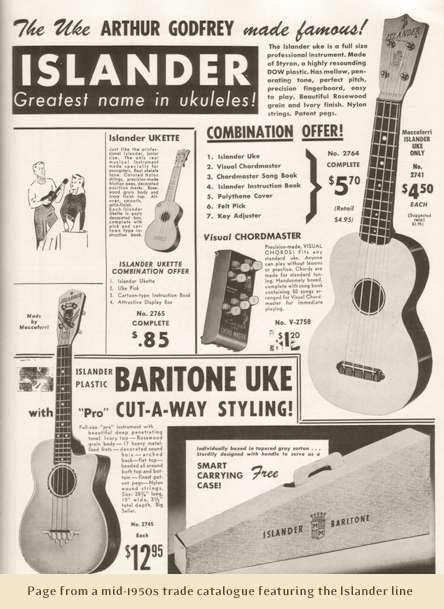

For a finishing touch, Islanders were surface treated and waxed and packaged in re-usable polyethylene bags secured at the top with rubber bands! They retailed for $5.95 (later reduced to $3.95), and cost about $1.50 to make. Maccaferri said he made 25 cents on each instrument and the rest went to middlemen. The Islander line eventually featured several other products including an extended fingerboard model, a baritone ukulele, a child’s-sized Ukette, and a patented chording device called the Visual Chordmaster. Mastro Plastics Corp. continued making ukuleles well into the 1960s. For a finishing touch, Islanders were surface treated and waxed and packaged in re-usable polyethylene bags secured at the top with rubber bands! They retailed for $5.95 (later reduced to $3.95), and cost about $1.50 to make. Maccaferri said he made 25 cents on each instrument and the rest went to middlemen. The Islander line eventually featured several other products including an extended fingerboard model, a baritone ukulele, a child’s-sized Ukette, and a patented chording device called the Visual Chordmaster. Mastro Plastics Corp. continued making ukuleles well into the 1960s.

Applied music

n 1952, an American educator addressed the shortage of string players in schools by introducing experimental pre-string training classes for fourth-graders using ukuleles. William Mihalyi was inspired by a talk he heard at the first annual conference of ASTA (American String Teachers Association) in 1951 extolling the use of ukuleles to teach both vocal and instrumental music at the same time. Mihalyi wrote: n 1952, an American educator addressed the shortage of string players in schools by introducing experimental pre-string training classes for fourth-graders using ukuleles. William Mihalyi was inspired by a talk he heard at the first annual conference of ASTA (American String Teachers Association) in 1951 extolling the use of ukuleles to teach both vocal and instrumental music at the same time. Mihalyi wrote:

Upon my return home, I immediately contacted my supervisor, who agreed to try ukuleles for a pre-string training program. After considerable investigation we chose plastic ukuleles with nylon strings as the instrument to use in this experiment. The tone was fine, the construction showed attention to detail, and the possibility of “long life” seemed to be present.

The instrument Mihalyi chose was the Islander Ukette. And it opened his eyes. “Without a doubt there are those who will turn up their noses at the thought of using ukuleles in schools. It is not the accepted thing! I, myself, felt that way at one time. I had been taught to look down on certain instruments as being of a lower form than others. Such thoughts are now disappearing from my mind.” It’s not clear if the program ever progressed beyond the experimental stage (unlike the Canadian program introduced by Chalmers Doane), but results were apparently beyond expectations. Students interested in the violin made the change from ukette to fiddle easily. And Mihalyi noted another possible benefit from including the ukulele in a larger music curriculum: “Even in later life playing the ukulele could be a source of enjoyment in the home.” Was he predicting the Third Wave?

References from Modern Plastics, the Wall Street Journal, Newsweek, Music Educators Journal, and Fortune were used in this article. |

|

|

© 2007, John King & Nalu Music. All rights reserved. Do not reproduce without permission. |

| © 2010, Antoine Carolus. This site has been made with a head, two hands and a computer but no webdesign or HTML editing software (fatto a mano). |

|